Robotics WorkStation - STARline

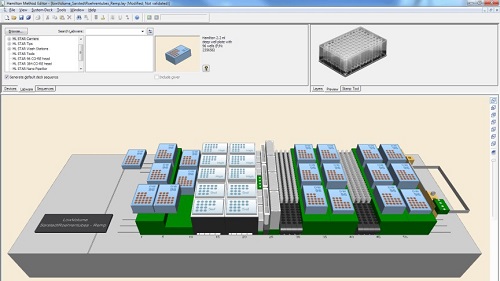

The STAR line workstations are based on superior air displacement pipetting technology. This increases accuracy and repeatability while providing chain of custody with pipette condition monitoring and recording. Each workstation can be configured with multiple arms and each arm can be configured with multiple pipetting and labware gripping devices. Pipetting channels and labware grippers move independently of each other, supporting the use of a wide range of labware. The autoload option provides barcode tracking of samples, labware, racks and carriers. All workstation functions and integrated third-party devices are controlled by the Venus software.

- CO-RE Technology: Hamilton uses quality engineered components and the CO-RE tip attachment technology. The CO-RE system attaches disposable tips or washable steel tips to the pipetting channels with a stable lock-and-key fit and a precision of ±0.1 mm in all axes.

- Liquid Level Detection: Hamilton offers both the traditional capacitive liquid level detection as well as pressure based liquid level detection. The software can use these functions to drive the pipette tip to just above the surface to do a jet dispense, or touch the surface for a wet dispense, or dive below sufficiently to aspirate liquid without drawing in any air.

- Monitored Air Displacement: Monitoring air displacement allows for real time detection of pipetting errors during pipetting steps. This includes detecting if an insufficient amount of liquid has been aspirated for a single, multiple or partial dispense; spiration of air, because the level of the liquid in a reservoir/tube was too low; and blocked tips due to clotting.

- Anti Droplet Control: The combination of CO-RE technology and air displacement pipetting with pressure monitoring allows Hamilton to offer anti droplet control (ADC). Now you can pipette liquids with extremely low viscosity and high vapor pressure like Acetone and Methanol with ease and confidence knowing that there will be no loss of liquid and no contamination of other samples because of dripping tips.

- Flexible and Precise tip Positioning: The STAR’s Dynamic Positioning System allows each pipetting channel to move independently in both the Y- and Z-axes. Each channel uses its own high-precision motors and electronics to reach any position on the deck. In applications such as hit-picking, where samples need to be transferred in an irregular pattern, this flexibility improves throughput. Since it is possible to have up to 16 channels on the same arm, multiple microplates may be processed simultaneously, drastically increasing throughput.

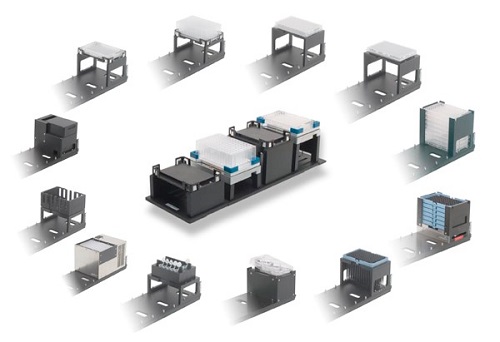

- Modular pipetting heads, deck layouts and accessories for application.

- Compatible with sample tubes, microplates, and custom labware.

- Barcode identification for samples, microplates, reagents and carriers.

- Data output in multiple formats for LIMS integration.

- Open system with wide integration possibilities for different brands of reader, washers, incubators, etc.

- Microplate storage/stacking on deck.

- Cooling, heating, shaking, positive pressure extraction, etc available for configuring for specific workflow.