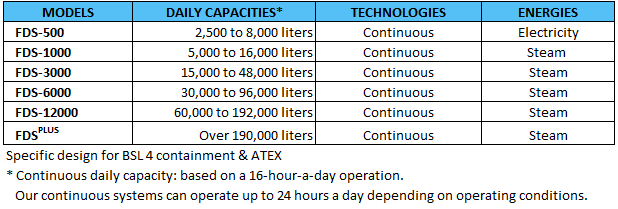

Continuous (FDS) Flow Thermal Decontamination Solutions

ACTINI has designed a unique continuous flow thermal decontamination solutions. Our standard range of continuous decontamination systems treats from 500 to more than 12,000 liters of effluent per hour, which is ideal to treat large volumes of effluent.

Decontamination

- Heat treatment with F0 from 25 to 50 depending on the required safety levels

- Standard set 135°C for 2 minutes, adjustable according to specifications (conventional or unconventional germs)

- Compliance with the highest requirements for containment BSL3 – BSL4 / SIL3

Design

- Tubular design allowing continuous treatment of large volumes

- All welded heat exchangers to avoid any risk of leakage and cross-contamination

- Materials chosen according to the aggressiveness of the agents present in the effluent (strong resistance to chlorides)

- Steam or all-electric heating (patented technologies)

- Energy recovery section (savings of 80% of thermal energy used)

- Compact design

- Compliance with European or American standards

Operation & Advantages

- Fully automatic operation; cycles controlled by PLC (level control for automatic starts and stops, CIP cycles and sanitization) and records

- Redundant control of decontamination parameters (time / temperature and pressure for the Prion)